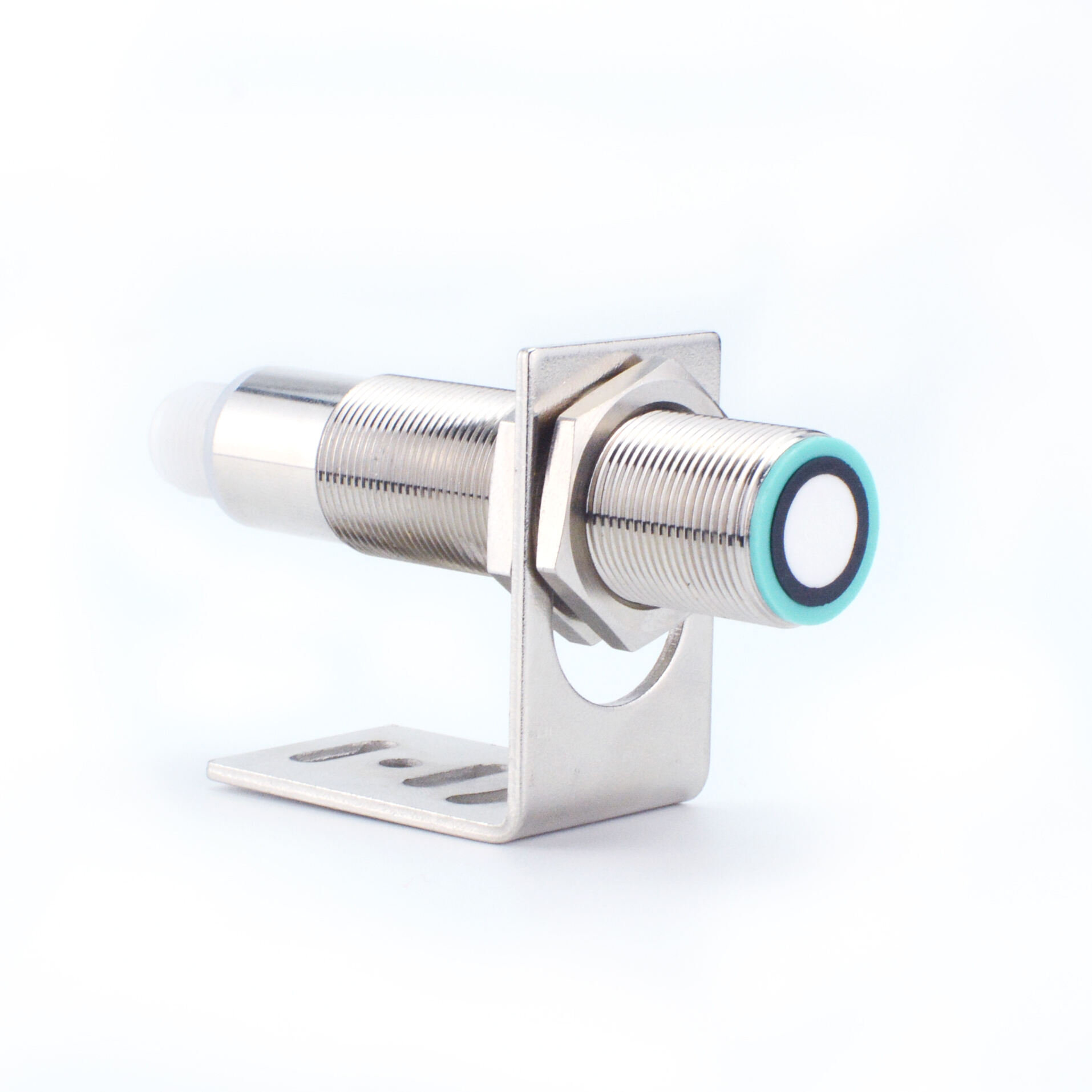

proximity detector

A proximity detector is a sophisticated electronic device designed to detect the presence or absence of nearby objects without physical contact. Operating through electromagnetic fields, infrared radiation, or ultrasonic waves, these devices serve as crucial components in various industrial and consumer applications. The detector emits a signal and analyzes the returned reflection to determine an object's presence and distance. Modern proximity detectors incorporate advanced microprocessor technology, enabling precise measurements and rapid response times, typically within milliseconds. These devices can be configured for different detection ranges, from a few millimeters to several meters, depending on the specific application requirements. They offer multiple output options, including digital, analog, and network communications, making them versatile for integration into various control systems. Proximity detectors feature robust construction to withstand harsh industrial environments, with many models offering IP67 protection ratings against dust and water. They also include diagnostic capabilities for self-monitoring and maintenance prediction, ensuring reliable operation in critical applications. The technology supports various mounting options and can be easily integrated into existing automation systems, making them essential tools in modern manufacturing and security applications.