Selecting the appropriate limit switch for industrial equipment represents a critical decision that directly impacts operational efficiency, safety protocols, and maintenance costs. Industrial facilities across manufacturing, automation, and process control sectors rely heavily on these essential components to monitor position, detect movement, and ensure proper system functionality. The wrong choice can lead to premature failures, safety hazards, and costly downtime that disrupts production schedules.

Modern industrial applications demand precise control mechanisms that can withstand harsh operating environments while delivering consistent performance. A properly selected limit switch serves as the interface between mechanical movement and electrical control systems, providing crucial feedback that enables automated processes to function safely and efficiently. Understanding the various types, specifications, and application requirements becomes essential for engineers and maintenance professionals responsible for equipment selection and installation.

Understanding Limit Switch Fundamentals

Basic Operating Principles

The fundamental operation of a limit switch relies on mechanical actuation that triggers electrical contact changes within the device. When a moving component reaches a predetermined position, it physically contacts the actuator arm or plunger, causing internal contacts to either open or close depending on the switch configuration. This mechanical-to-electrical conversion provides reliable position feedback that control systems use to initiate subsequent actions or safety shutdowns.

Most limit switch designs incorporate a snap-action mechanism that ensures rapid contact transition regardless of actuator speed. This characteristic prevents contact arcing and extends operational life by minimizing the time spent in intermediate positions. The internal spring-loaded mechanism stores energy during actuator movement and releases it quickly when the switching point is reached, creating a definitive on-off signal that control circuits can interpret reliably.

Contact arrangements vary significantly based on application requirements, with common configurations including normally open, normally closed, and changeover contacts. Some advanced models feature multiple contact sets within a single housing, allowing simultaneous control of multiple circuits or providing redundant switching capability for critical safety applications. Understanding these basic principles helps engineers select appropriate contact configurations for specific control requirements.

Key Components and Construction

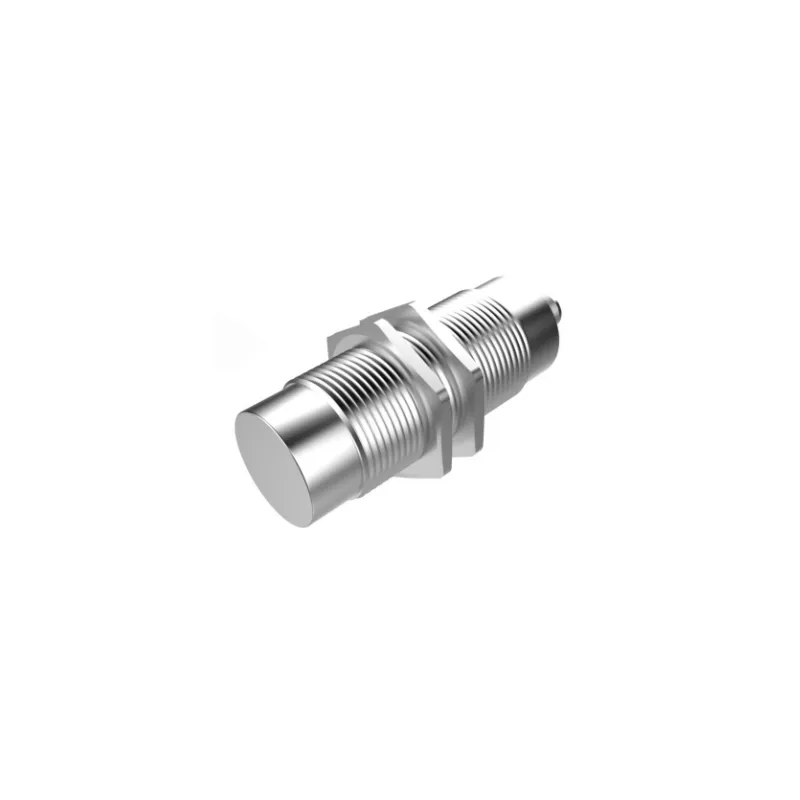

The housing construction of a limit switch determines its ability to withstand environmental conditions and mechanical stresses encountered in industrial applications. Cast aluminum, stainless steel, and engineered plastic housings each offer distinct advantages depending on factors such as corrosion resistance, weight constraints, and electromagnetic compatibility requirements. Proper housing selection ensures long-term reliability in challenging operating environments.

Internal contact materials significantly influence switching capacity, contact resistance, and operational lifespan. Silver-cadmium oxide contacts provide excellent conductivity and arc resistance for general-purpose applications, while gold-plated contacts offer superior performance in low-current signal switching applications. Tungsten contacts excel in high-current applications where contact welding must be minimized, making material selection crucial for optimal performance.

Actuator design varies considerably based on application requirements, with options including roller plungers, adjustable rod actuators, lever arms, and rotary cams. Each actuator type offers specific advantages in terms of operating force, travel distance, and directional sensitivity. The actuator mechanism must align with the mechanical characteristics of the equipment being monitored to ensure reliable operation throughout the expected service life.

Environmental and Operating Conditions

Temperature and Climate Considerations

Operating temperature ranges significantly impact limit switch performance and longevity, requiring careful consideration of ambient conditions and thermal cycling effects. Standard industrial models typically operate reliably within -25°C to +70°C ranges, while specialized high-temperature variants can withstand conditions up to +200°C for applications near furnaces, ovens, or heat-generating equipment. Cold temperature applications may require special lubricants and materials to prevent mechanical binding or contact oxidation.

Humidity and moisture exposure can cause internal corrosion, contact degradation, and insulation breakdown if not properly addressed through appropriate sealing and material selection. IP67 and IP68 rated enclosures provide protection against water ingress, while conformal coatings on internal components offer additional protection against condensation and chemical vapors. Marine and offshore applications often require special attention to salt spray resistance and cathodic protection considerations.

Thermal shock conditions, where rapid temperature changes occur during operation, can stress housing materials and affect dimensional stability of internal components. Selecting a limit switch with appropriate thermal expansion coefficients and stress-relief features becomes critical for applications involving cyclic heating and cooling processes such as those found in steel mills or glass manufacturing facilities.

Mechanical Stress and Vibration

Industrial environments often subject limit switches to significant mechanical stresses including shock, vibration, and repetitive actuation forces that can cause premature wear or failure. Vibration resistance ratings, typically expressed in terms of frequency range and acceleration limits, help determine suitability for installation on rotating machinery, conveyor systems, or mobile equipment where continuous motion creates challenging operating conditions.

Mounting orientation and support structure design play crucial roles in minimizing stress concentration and ensuring proper actuator alignment throughout the equipment's operational life. Flexible mounting systems can isolate the limit switch from excessive vibration while maintaining proper position sensing accuracy. Solid mounting may be preferred in precision applications where position repeatability takes priority over vibration isolation.

Actuator force requirements must balance sensitivity with durability, ensuring reliable switching while withstanding the mechanical forces encountered during normal operation. Over-travel capability allows the switch to handle situations where the actuating mechanism moves beyond the nominal switching point without damage. Pre-travel and over-travel specifications help engineers design mechanical interfaces that optimize switch performance and longevity.

Electrical Specifications and Load Compatibility

Current and Voltage Ratings

Proper electrical rating selection ensures that the limit switch can safely handle the connected load without contact degradation or failure. Current ratings encompass both continuous current capacity and switching current capability, which may differ significantly based on load characteristics and duty cycle requirements. Inductive loads such as motor contactors and solenoid valves require higher switching capacity due to arc formation during contact opening.

Voltage ratings must accommodate both the nominal system voltage and any transient overvoltages that may occur during switching operations or fault conditions. AC and DC switching characteristics differ substantially, with DC applications often requiring higher voltage ratings due to the absence of natural current zero crossings that facilitate arc extinction. Many modern limit switches provide dual ratings to accommodate both AC and DC applications within the same device.

Contact life expectancy varies significantly based on electrical load characteristics, with resistive loads providing the longest service life and inductive loads presenting the greatest challenges for contact longevity. Load current, switching frequency, and environmental conditions all influence contact wear rates, requiring careful analysis of application requirements to predict maintenance intervals and lifecycle costs.

Signal Processing and Interface Requirements

Modern control systems often require specific signal characteristics from limit switches to ensure proper interface compatibility and noise immunity. Digital control systems may benefit from proximity sensors or smart limit switches that provide standardized output signals with built-in signal conditioning and filtering capabilities. These advanced devices can eliminate external interface circuitry while providing enhanced diagnostic capabilities.

Signal integrity becomes particularly important in applications with long cable runs or electrically noisy environments where electromagnetic interference can cause false triggering or signal degradation. Shielded cables, twisted pair construction, and proper grounding techniques help maintain signal quality, while some limit switch designs incorporate internal filtering and surge protection to improve system reliability.

Response time requirements must align with the dynamic characteristics of the controlled process to ensure proper system operation and safety function performance. Mechanical limit switches typically provide response times in the millisecond range, which proves adequate for most industrial applications. However, high-speed processes may require electronic sensing technologies that offer microsecond response capabilities.

Application-Specific Selection Criteria

Safety and Emergency Stop Applications

Safety-critical applications require limit switches that meet specific performance standards and certification requirements such as those outlined in IEC 61508 or ISO 13849. Positive-opening contacts ensure that mechanical failure of the actuator mechanism cannot prevent safety circuit de-energization, providing fail-safe operation even under single-fault conditions. These applications often require redundant switching elements and diagnostic monitoring capabilities.

Emergency stop circuits demand limit switches with high reliability ratings and predictable failure modes that align with overall system safety integrity levels. Force-guided contacts prevent contact welding from compromising safety function operation, while mechanical design features ensure that internal failures result in safe circuit de-energization rather than dangerous undetected failures.

Documentation and traceability requirements for safety applications often mandate specific testing protocols, certification marks, and maintenance procedures that must be considered during the selection process. Regular functional testing and calibration schedules help maintain safety system integrity throughout the operational lifecycle, requiring limit switches that can withstand frequent testing without performance degradation.

Precision Positioning and Automation

Precision automation applications require limit switches with exceptional repeatability and minimal hysteresis to ensure consistent positioning accuracy. Mechanical backlash, temperature drift, and wear characteristics all influence positioning repeatability, making component quality and manufacturing tolerances critical selection factors. Some applications may benefit from adjustable switching points or multiple switching positions within a single device.

High-speed automation systems place demanding requirements on limit switch response time and mechanical durability due to frequent actuation cycles and rapid actuator movement. Ball bearing actuator mechanisms and precision-machined components help minimize wear and maintain performance characteristics throughout extended service intervals, while sealed construction prevents contamination from affecting internal mechanisms.

Integration with programmable logic controllers and distributed control systems may require specific communication protocols or analog output signals that provide position information rather than simple on-off switching. Smart limit switches with fieldbus connectivity can provide enhanced diagnostic information and remote configuration capabilities that simplify system integration and maintenance procedures.

Installation and Maintenance Considerations

Mounting and Alignment Procedures

Proper mounting techniques ensure optimal limit switch performance and longevity by minimizing stress concentrations and maintaining accurate actuator alignment throughout the equipment's operational life. Mounting bracket design must accommodate thermal expansion, vibration isolation, and adjustment requirements while providing adequate mechanical support for the switching forces encountered during operation.

Actuator alignment affects both switching accuracy and mechanical wear characteristics, requiring careful attention to approach angle, contact force, and over-travel allowances. Misalignment can cause premature actuator wear, unreliable switching, or mechanical binding that prevents proper operation. Installation procedures should include verification of proper alignment under all anticipated operating conditions.

Cable routing and electrical connections must follow good engineering practices to prevent mechanical damage, electromagnetic interference, and moisture ingress. Strain relief fittings protect cable connections from mechanical stress, while proper conduit sealing prevents moisture accumulation that could cause corrosion or insulation breakdown. Connection torque specifications help ensure reliable electrical contact without mechanical damage to terminals.

Preventive Maintenance and Troubleshooting

Regular inspection schedules help identify potential limit switch problems before they result in equipment failures or safety hazards. Visual inspection of housing condition, actuator alignment, and cable integrity provides early warning of developing problems that could affect operational reliability. Electrical testing of contact resistance and insulation integrity helps assess internal component condition and predict remaining service life.

Lubrication requirements vary based on limit switch design and operating environment, with some sealed units requiring no maintenance while others benefit from periodic application of appropriate lubricants. Over-lubrication can attract contamination and cause actuator binding, while insufficient lubrication may result in excessive wear and mechanical failure. Following manufacturer recommendations ensures optimal performance and service life.

Replacement criteria should consider both safety implications and economic factors, with safety-critical applications requiring more conservative replacement intervals than general industrial applications. Trending of maintenance data helps identify degradation patterns and optimize replacement schedules based on actual operating conditions rather than arbitrary time intervals.

Cost Analysis and Selection Process

Total Cost of Ownership Evaluation

Initial purchase price represents only a small portion of the total cost of ownership for industrial limit switches, with installation costs, maintenance requirements, and failure consequences often exceeding the original device cost. High-quality limit switches with superior durability and reliability characteristics may justify higher initial costs through reduced maintenance requirements and extended service intervals.

Failure consequences vary dramatically based on application criticality, with safety-related failures potentially resulting in regulatory penalties, liability issues, and reputation damage that far exceed direct replacement costs. Production downtime costs often dwarf equipment costs in continuous process applications, making reliability and availability key economic factors in the selection process.

Standardization benefits can reduce inventory costs, simplify maintenance procedures, and improve technician familiarity with equipment characteristics. However, standardization must be balanced against application-specific requirements that may demand specialized limit switch features or performance characteristics not available in standard product lines.

Supplier Evaluation and Support Services

Technical support capabilities become increasingly important for complex applications requiring application engineering assistance, custom modifications, or troubleshooting support. Suppliers with strong technical resources can provide valuable assistance during the selection process and ongoing operational support that justifies premium pricing for their products.

Product availability and delivery performance affect project schedules and emergency replacement scenarios, making supplier reliability and inventory management capabilities important selection factors. Global suppliers with local distribution networks often provide better availability and shorter lead times for both standard and specialized limit switch products.

Warranty terms and service policies provide insight into manufacturer confidence in their products while establishing expectations for post-purchase support. Extended warranty coverage may indicate superior product quality, while comprehensive service policies demonstrate commitment to customer satisfaction and long-term product support.

FAQ

What factors determine the appropriate current rating for a limit switch?

The current rating selection depends on the connected load characteristics, including steady-state current requirements and inrush current during switching operations. Inductive loads such as contactors and solenoids typically require higher switching capacity due to arc formation, while resistive loads are less demanding. Consider both continuous current capacity and switching current capability, as these ratings may differ significantly based on duty cycle and load type.

How do environmental sealing ratings affect limit switch selection?

Environmental sealing ratings such as IP65, IP67, and IP68 indicate the level of protection against dust and water ingress. IP67 ratings provide adequate protection for most industrial applications including temporary immersion, while IP68 ratings are required for continuous submersion applications. Higher protection ratings may increase cost and size, so select the minimum rating that meets actual environmental conditions rather than over-specifying unnecessarily.

What maintenance procedures are recommended for industrial limit switches?

Regular visual inspection of housing condition, actuator alignment, and cable integrity should be performed according to manufacturer recommendations, typically every 3-6 months for critical applications. Electrical testing of contact resistance and insulation integrity helps assess internal component condition. Clean external surfaces to prevent contamination buildup, and verify proper actuator operation under no-load conditions to identify developing mechanical problems before they cause failures.

How do I determine the correct actuator type for my application?

Actuator selection depends on the mechanical interface requirements including approach direction, available space, and required operating force. Roller plungers work well for linear motion detection, while lever arms provide mechanical advantage for low-force applications. Consider factors such as over-travel capability, reset characteristics, and adjustment range when matching the actuator to your specific mechanical requirements and installation constraints.