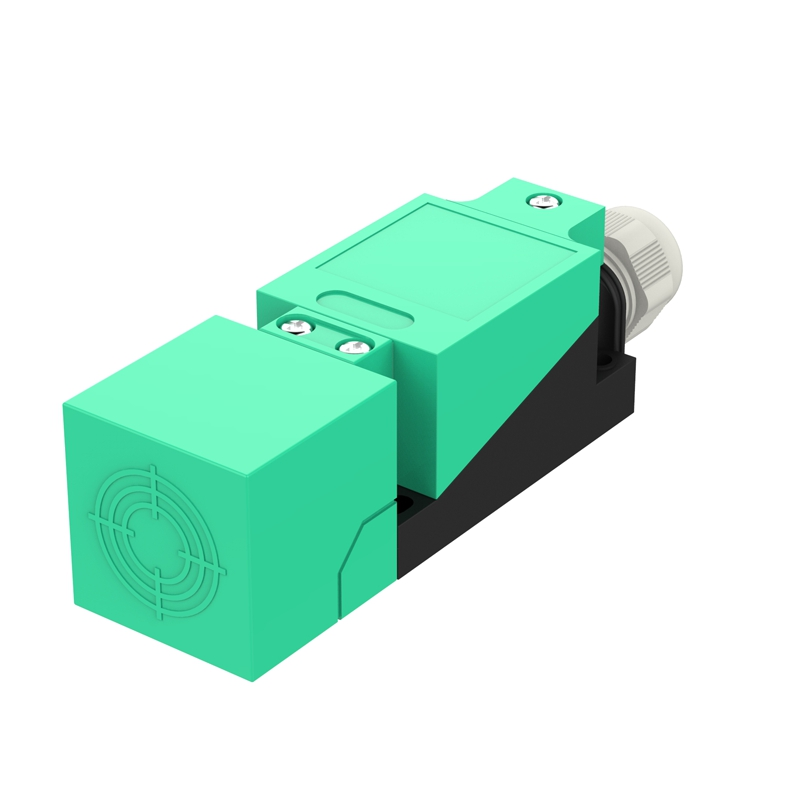

funcionamento do sensor ultrasonico

Os principios de funcionamento dos sensores ultrasónicos xiran arredor da emisión e recepción de ondas sonoras fóra do rango auditivo humano. Estes dispositivos operan enviando pulsos de son de alta frecuencia e medindo o tempo que tarda o eco en regresar despois de golpear un obxecto. O transdutor do sensor actúa tanto como transmisor como receptor, convertendo a enerxía eléctrica en ondas sonoras e viceversa. Operando en frecuencias tipicamente entre 40 kHz e 70 kHz, estes sensores fornecen medidas precisas de distancia aproveitando a velocidade do son no aire. O mecanismo de funcionamento inclúe un temporizador que se inicia cando se emite o pulso e detense cando o eco regresa, permitindo cálculos precisos de distancia. Os sensores ultrasónicos modernos incorporan algoritmos sofisticados de procesamento de sinal para filtrar o ruído e asegurar medidas fiabres. Destacan en diversos ambientes, mantendo a súa efectividade en condicións de pouca luz e con superficies transparentes ou reflectantes. A tecnoloxía ten aplicacións en múltiples industrias, desde sensores de aparcado automotriz ata automatización industrial, monitorización de nivel de líquidos e robótica. A súa capacidade de funcionar sen contacto físico fainos ideais para medir distancias a materiais delicados ou perigosos.