ultrasonic sensor for industrial automation

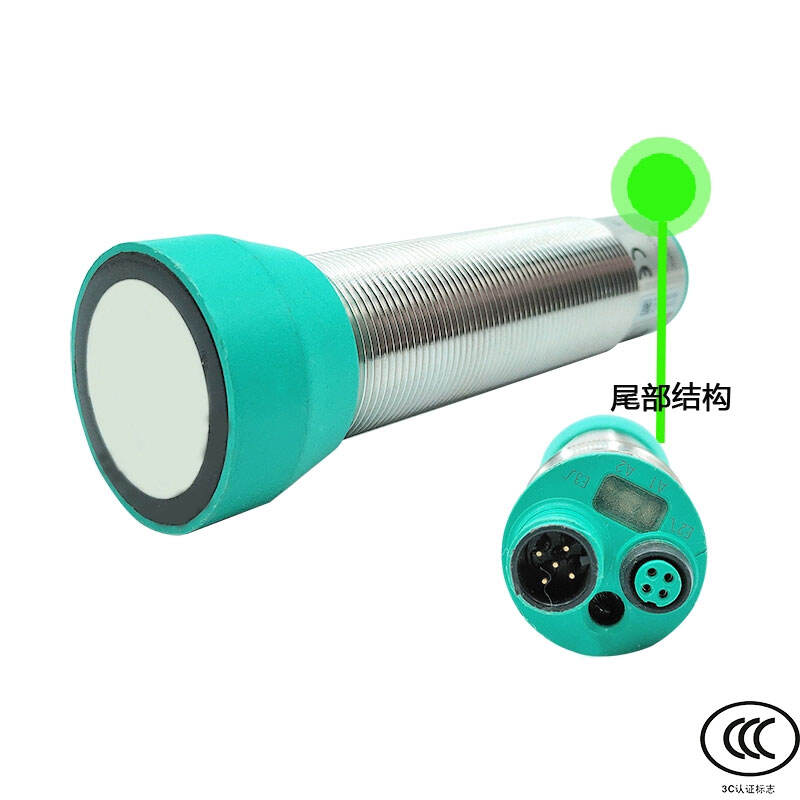

Ultrasonic sensors represent a cornerstone technology in industrial automation, offering non-contact detection and measurement capabilities essential for modern manufacturing processes. These sophisticated devices operate by emitting high-frequency sound waves and measuring the time taken for the echo to return, enabling precise distance measurement and object detection. In industrial automation settings, ultrasonic sensors excel in various applications, from level measurement in tanks to presence detection on assembly lines. The technology incorporates advanced signal processing capabilities that filter out ambient noise and ensure reliable readings even in challenging industrial environments. These sensors can detect objects regardless of their color, transparency, or material composition, making them versatile tools for diverse industrial applications. The measurement range typically extends from a few centimeters to several meters, with many models offering adjustable sensing ranges to suit specific application requirements. Modern ultrasonic sensors often feature digital displays, multiple output options (including analog and digital), and easy-to-use teaching functions for quick setup and calibration. Their robust construction typically includes IP67 or IP68 ratings, ensuring reliable operation in dusty, wet, or harsh industrial environments. The integration capabilities of these sensors with existing automation systems through various communication protocols make them essential components in Industry 4.0 applications.