Revolutionizing Industrial Sensing Technology with Ultrasonic Solutions

Modern industrial processes demand precise, reliable, and versatile sensing technologies to maintain operational excellence. Ultrasonic sensors have emerged as a cornerstone technology in industrial applications, offering unparalleled advantages in measurement, detection, and process control. These sophisticated devices utilize sound waves beyond human hearing range to deliver accurate measurements and detection capabilities across diverse industrial environments.

The integration of ultrasonic sensor technology has transformed manufacturing, material handling, and quality control processes. By employing high-frequency sound waves, these sensors provide non-contact measurement solutions that overcome limitations of traditional sensing methods, making them invaluable across numerous industrial sectors.

Core Benefits of Ultrasonic Sensing Technology

Superior Accuracy and Reliability

Industrial ultrasonic sensor systems deliver exceptional measurement accuracy, typically achieving precision levels within millimeters. This high degree of accuracy remains consistent across varying environmental conditions, making these sensors ideal for critical industrial processes where precision is paramount.

The reliability of ultrasonic sensor technology stems from its robust design and resistance to external factors. Unlike optical sensors, ultrasonic devices maintain performance regardless of target object color, transparency, or surface reflection properties, ensuring dependable operation in challenging industrial settings.

Versatility in Applications

The adaptability of ultrasonic sensor technology extends across numerous industrial applications. From level measurement in storage tanks to presence detection on assembly lines, these sensors excel in diverse operational contexts. Their ability to detect various materials, including liquids, solids, and granular substances, makes them exceptionally versatile.

Manufacturing facilities particularly benefit from ultrasonic sensor implementation in quality control processes, where precise measurements and consistent detection capabilities are essential. The technology's versatility also supports efficient inventory management and material handling systems.

Environmental Performance and Durability

Resistance to Harsh Conditions

Industrial environments often present challenging conditions that can compromise sensor performance. Ultrasonic sensor technology demonstrates remarkable resilience in these situations, maintaining functionality in the presence of dust, moisture, and various atmospheric contaminants. This robustness significantly reduces maintenance requirements and extends operational lifespan.

The sealed construction of ultrasonic sensors provides protection against industrial pollutants while ensuring consistent performance in extreme temperature ranges. This environmental adaptability makes them particularly valuable in chemical processing, mining, and heavy manufacturing applications.

Sustainable Operation

The non-contact nature of ultrasonic sensor operation contributes to sustainable industrial practices. By eliminating physical contact with measured objects, these sensors reduce wear and maintenance requirements while extending service life. This characteristic aligns with modern industrial sustainability goals and supports long-term cost efficiency.

Energy efficiency represents another significant advantage of ultrasonic sensor technology. These devices typically consume minimal power while delivering continuous, reliable performance, contributing to reduced operational costs and environmental impact.

Integration and Implementation Advantages

Seamless System Integration

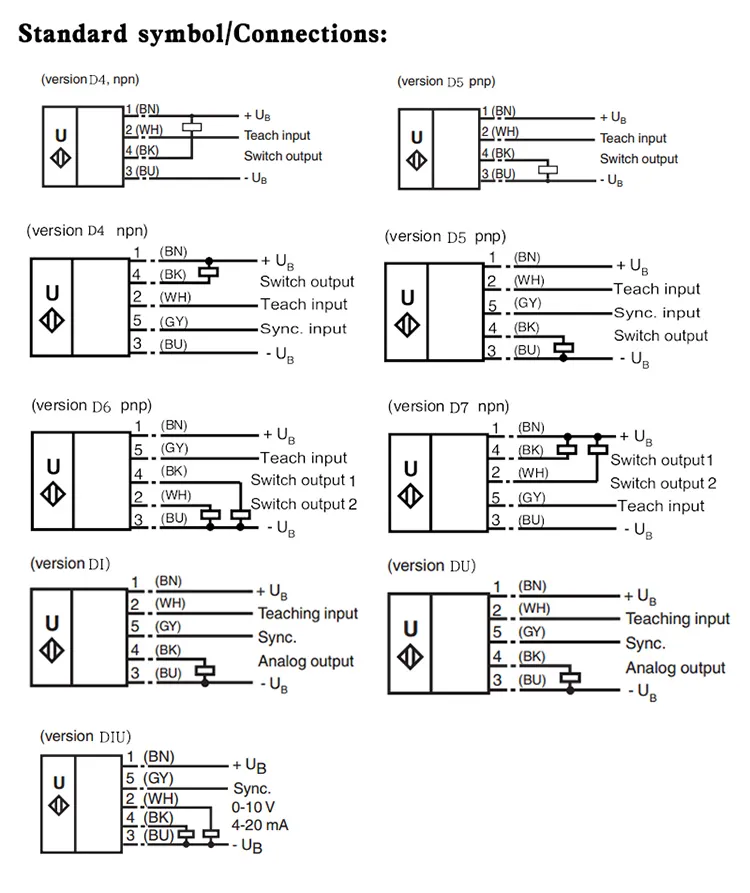

Modern ultrasonic sensor solutions offer straightforward integration with existing industrial control systems. Standard communication protocols and interfaces enable smooth incorporation into automated processes, while digital output options facilitate direct connection to PLCs and control systems.

The flexibility of ultrasonic sensor implementation extends to both retrofit applications and new installations. This adaptability, combined with minimal setup requirements, enables rapid deployment and reduced downtime during system upgrades.

Cost-Effective Solutions

When evaluating long-term operational costs, ultrasonic sensor technology presents compelling advantages. The combination of minimal maintenance requirements, extended service life, and reliable performance contributes to favorable total cost of ownership compared to alternative sensing technologies.

Initial investment in ultrasonic sensor systems often yields significant returns through improved process efficiency, reduced downtime, and decreased maintenance expenses. The technology's durability and reliability minimize replacement needs, further enhancing cost-effectiveness.

Future Developments and Industry Trends

Advanced Features and Capabilities

The evolution of ultrasonic sensor technology continues to introduce enhanced capabilities and features. Integration with IoT platforms enables advanced data analytics and predictive maintenance capabilities, while improved signal processing algorithms enhance measurement accuracy and reliability.

Emerging developments in sensor miniaturization and power efficiency promise to expand application possibilities while reducing implementation costs. These advancements position ultrasonic sensor technology at the forefront of industrial sensing solutions.

Industry 4.0 Integration

As manufacturing facilities embrace Industry 4.0 principles, ultrasonic sensor technology plays an increasingly vital role in smart factory implementations. Enhanced connectivity options and digital integration capabilities support real-time monitoring and advanced process control applications.

The ability to provide accurate, reliable data for industrial automation systems makes ultrasonic sensor technology essential for modern manufacturing environments. This alignment with Industry 4.0 requirements ensures continued relevance and expanding applications.

Frequently Asked Questions

What maximum range can ultrasonic sensors achieve in industrial applications?

Industrial ultrasonic sensors typically offer detection ranges from a few centimeters to several meters, with some specialized models capable of measurements up to 15 meters or more. The exact range depends on the specific sensor model and environmental conditions.

How do environmental factors affect ultrasonic sensor performance?

While ultrasonic sensors are generally robust, extreme temperature variations and high-humidity environments can influence measurement accuracy. However, modern sensors incorporate temperature compensation and specialized housing designs to maintain reliable performance across diverse conditions.

What maintenance requirements do ultrasonic sensors have?

Ultrasonic sensors require minimal maintenance due to their non-contact operation. Regular cleaning of the sensor face to remove dust or debris, along with periodic calibration checks, typically suffices to ensure optimal performance. This low maintenance requirement contributes to their cost-effectiveness in industrial applications.