ultrasonic level controller

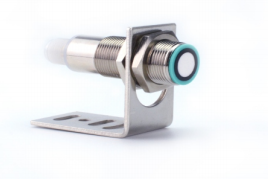

An ultrasonic level controller is a sophisticated measurement device that utilizes sound waves to determine liquid or solid material levels in various containers and vessels. Operating on the principle of echo-location, it emits high-frequency sound pulses that bounce off the material surface and return to the sensor. The device calculates the distance by measuring the time taken for the signal to return, providing accurate level measurements without direct contact with the medium. The controller consists of a transducer that both transmits and receives ultrasonic signals, a processing unit that converts time measurements into distance readings, and a display interface that shows real-time level information. Modern ultrasonic level controllers incorporate advanced features such as temperature compensation, automatic calibration, and multiple alarm thresholds. These devices find extensive applications across industries, including water treatment facilities, chemical processing plants, food and beverage manufacturing, and oil storage tanks. The non-contact nature of measurement makes them particularly suitable for corrosive, sticky, or hazardous materials where traditional contact sensors might fail or deteriorate. With their ability to provide continuous monitoring and integration capabilities with various control systems, ultrasonic level controllers have become essential tools in modern industrial automation and process control.