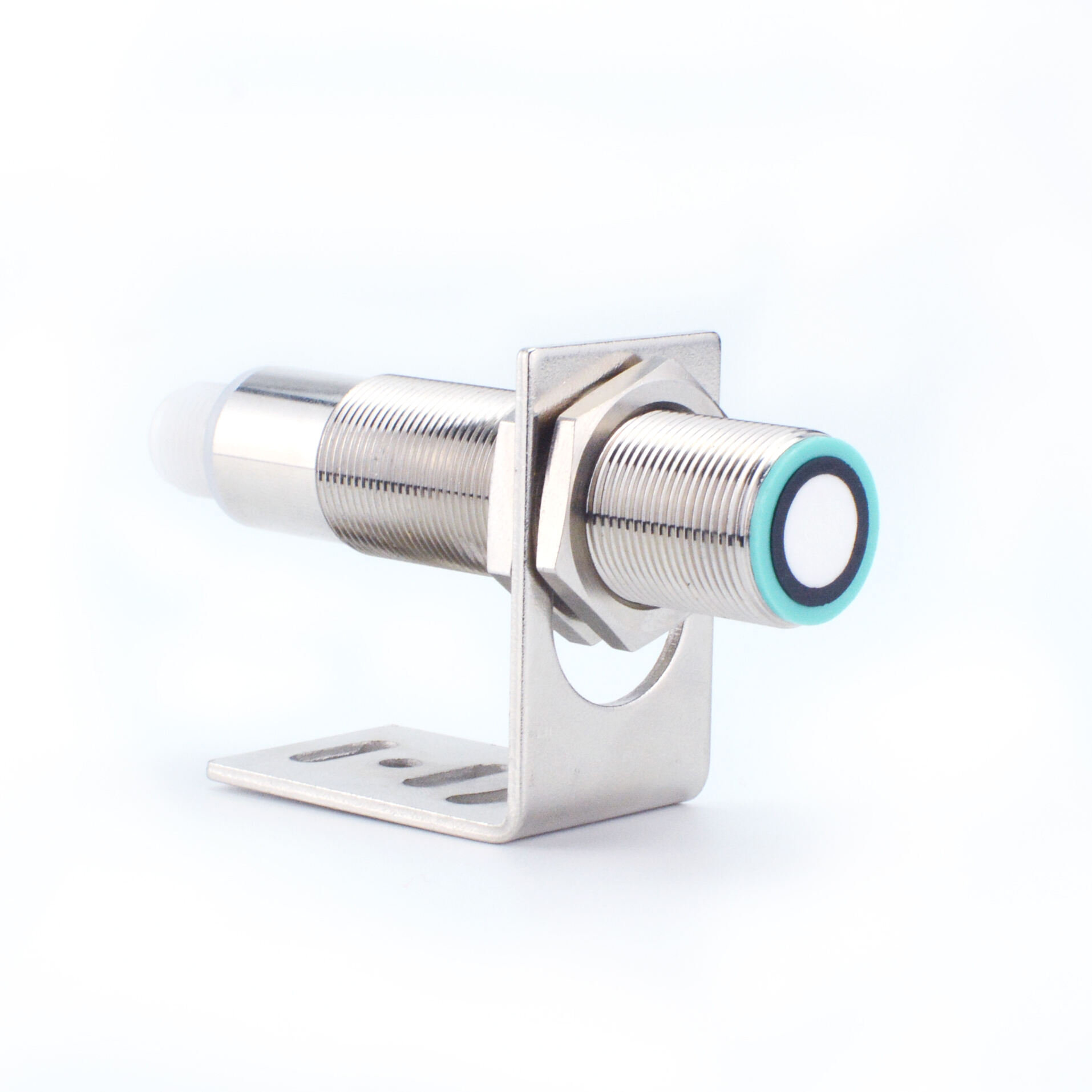

photoelectric sensor for packaging machines

Photoelectric sensors for packaging machines are sophisticated detection devices that play a crucial role in modern automated packaging operations. These sensors utilize advanced light-based technology to detect, monitor, and control various aspects of the packaging process. They work by emitting a beam of light and measuring its reflection or interruption, enabling precise object detection and positioning. The sensors are specifically designed to operate in high-speed packaging environments, capable of detecting objects of various sizes, shapes, and materials with exceptional accuracy. Their robust construction ensures reliable performance in challenging industrial conditions, including environments with dust, moisture, and varying temperatures. These sensors can perform multiple functions, including product presence detection, position verification, label detection, and package alignment monitoring. They integrate seamlessly with packaging machine control systems through industry-standard interfaces, allowing for real-time adjustments and quality control. The technology incorporates advanced features such as background suppression, which helps eliminate false triggers from reflective surfaces, and digital filtering that ensures accurate readings even in challenging lighting conditions. Modern photoelectric sensors also offer adjustable sensitivity settings, multiple operating modes, and diagnostic capabilities that help maintain optimal performance and reduce maintenance requirements.