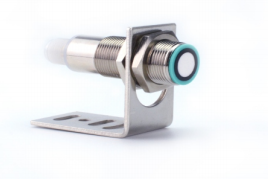

sensor för tanknivå utan kontakt

Sensornivåsensorer för tankar utgör en modern lösning för mätning av vätskenivåer i olika behållare utan fysisk kontakt med medium. Dessa sofistikerade enheter använder avancerade tekniker såsom ultraljud, radar eller laserstrålar för att exakt fastställa vätskenivåer. Sensorn sänder ut signaler som reflekteras från vätskeytan och återvänder till detektorn, vilket gör att avståndet beräknas baserat på tiden det tar för signalen att återvända. Detta moderna tillvägagångssätt säkerställer noggranna mätningar samtidigt som risken för föroreningar och mekanisk slitage, vilket är förknippat med traditionella kontaktsensorer, elimineras. Tekniken fungerar effektivt inom många industriella tillämpningar, från kemisk bearbetning till vattenbehandlingsanläggningar, och erbjuder möjlighet till övervakning i realtid med exceptionell noggrannhet. Dessa sensorer kan fungera tillförlitligt i svåra miljöer och bibehåller konsekvent prestanda trots variationer i temperatur, tryck eller kemisk sammansättning hos det uppmätta mediet. De stödjer integration med moderna styrsystem via standardiserade kommunikationsprotokoll, vilket möjliggör automatiserad övervakning och styrning av vätskenivåer. Den stora mångsidigheten hos sensornivåsensorer gör dem lämpliga för olika tankstorlekar och former, medan deras underhållsfria drift betydligt minskar driftskostnaderna. Deras förmåga att mäta genom skum, ånga och turbulenta förhållanden säkerställer tillförlitliga avläsningar i komplexa industriprocesser.