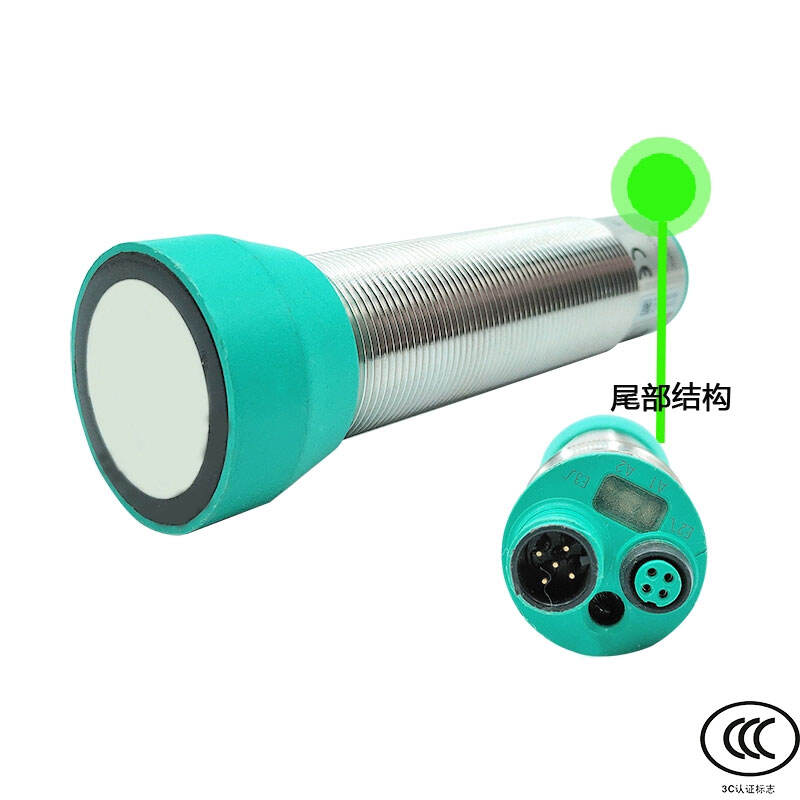

sensor ultrazanor për matjen e distancës

Një sensor ultrazanor për matjen e distancës paraqet një teknologji të sofistikuar por të besueshme, e cila funksionon duke lëshuar valë zanore me frekuencë të lartë dhe duke matur kohën që duhet këtyre valeve të kthehen pasi reflektohen nga një objekt. Ky parim i kohës së fluturimit lejon llogaritje të sakta të distancës, duke e bërë atë një mjet të pavlerë në shumë industri dhe aplikime. Sensori përbëhet nga dy komponentë kryesorë: një transmetues që lëshon valët ultrazanore dhe një pranues që zbulon sinjalet e reflektuara. Duke punuar në frekuenca mbi 20 kHz, këta sensorë mund të masin efektivisht distanca që variojnë nga disa centimetra deri në disa metra me saktësi të lartë. Teknologjia dallohet në mjedise të vështira ku sensorët optikë ose infrigjelbër mund të kenë vështirësi, si në kushte të pluhuritura, të errëta ose shumë të ndriçuara. Sensorët modernë ultrazanor përfshijnë mundësi të avancuara të përpunimit të sinjalit, kompensim temperaturash dhe modele të ndryshme rrezesh për të siguruar matje të sakta në skenare të ndryshme. Ato gjejnë zbatim të gjerë në automatizimin industrial, robotikë, sisteme ndihmëse parkimi, matje niveli në tangjera dhe zbulim pengesash në vetura autonome. Natyra pa kontakt e matjes i bën veçanërisht të përshtatshëm për aplikime ku kontakti fizik me objektin e synuar është i papëlqyer ose i pamundur.