gabiltzaile maila sensores ez-kontaktu

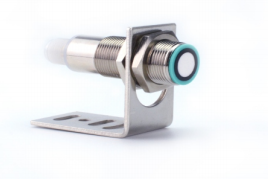

Kontaktu gabeko ontzi maila sensoreek ingurune desberdinetan likidoen mailak neurtzeko soluzio aurreratuak adierazten dituzte, eraginarekin kontakturik gabe. Gailu aurreratu hauek uhinen ultrasonikoak, radarra edo laser-izpiak bezalako teknologia aurreratuak erabiltzen dituzte fluidoen mailak zehazki zehazteko. Sentsoreak seinaleak igortzen ditu, likidoaren gainazalean islatu eta detektorean itzultzen direnak, seinaleak itzultzean behar duen denbora oinariz hartuta distantzia kalkulatuz. Hurbilketa moderno honek neurketak zehatzak bermatzen ditu, kontaktu-sentsore tradizionalen kasuan agertzen diren kontaminazio arriskua eta desgaste mekanikoa saihestuz. Teknologia honek industria aplikazio desberdinetan funtzionatzen du eraginkortasunez, prozesu kimikoetatik uraren tratamendura arte, erreala-denborako monitorizazioa eskainiz zehaztasun bikainarekin. Sentsore hauek ingurune zailenetan funtzionatu dezakete fidagarritasunez, errendimendua konstante mantenduz tenperatura, presio edo osagai kimikoen aldaketekiko arren. Sistema kontrol modernoetan integratzea ahalbidetzen dute komunikazio protokolo estandarren bidez, likidoen mailen monitorizazio eta kontrol automatizatua gauzatuz. Kontaktu gabeko ontzi maila sentsoreen aldaezintasunak tamaina eta formako ontzi desberdinetarako egokiak izaten ditu, eta mantenimendu gabeko erabilera kostu eragileak nabarmen murrizten ditu. Lurrin, lurrun eta baldintza turbulentuen zeharkatzean mailak neurtzeko gaitasunak irakurketa fidagarriak bermatzen ditu prozesu industrialean konplexuetan.