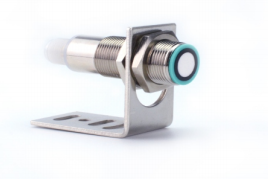

নন-কনট্যাক্ট ট্যাঙ্ক লেভেল সেন্সর

নন-কনট্যাক্ট ট্যাঙ্ক লেভেল সেন্সরগুলি মাধ্যমের সাথে শারীরিক যোগাযোগ ছাড়াই বিভিন্ন পাত্রে তরলের মাত্রা পরিমাপের জন্য একটি উন্নত সমাধান হিসাবে কাজ করে। এই উন্নত ডিভাইসগুলি অতিস্বনক তরঙ্গ, রাডার বা লেজার রশ্মি সহ অগ্রণী প্রযুক্তি ব্যবহার করে তরলের মাত্রা সঠিকভাবে নির্ধারণ করতে। সেন্সরটি এমন সংকেত নির্গত করে যা তরলের পৃষ্ঠে আঘাত করে এবং ডিটেক্টরে ফিরে আসে, সংকেতের ফিরে আসতে কত সময় লাগে তার ভিত্তিতে দূরত্ব গণনা করে। ঐতিহ্যগত কনট্যাক্ট সেন্সরগুলির সাথে যুক্ত দূষণ এবং যান্ত্রিক ক্ষয়ের ঝুঁকি এড়ানোর পাশাপাশি সঠিক পরিমাপ নিশ্চিত করে এই আধুনিক পদ্ধতি। রাসায়নিক প্রক্রিয়াকরণ থেকে শুরু করে জল চিকিৎসা সুবিধা পর্যন্ত বিভিন্ন শিল্প অ্যাপ্লিকেশনের মধ্যে এই প্রযুক্তি কার্যকরভাবে কাজ করে, অসাধারণ নির্ভুলতার সাথে রিয়েল-টাইম মনিটরিং সুবিধা প্রদান করে। পরিমাপ করা মাধ্যমের তাপমাত্রা, চাপ বা রাসায়নিক গঠনের পরিবর্তন সত্ত্বেও চ্যালেঞ্জিং পরিবেশে এগুলি নির্ভরযোগ্যভাবে কাজ করতে পারে, সামঞ্জস্যপূর্ণ কর্মক্ষমতা বজায় রাখে। এগুলি স্ট্যান্ডার্ড যোগাযোগ প্রোটোকলের মাধ্যমে আধুনিক নিয়ন্ত্রণ ব্যবস্থার সাথে একীভূত হওয়ার সুবিধা প্রদান করে, তরলের মাত্রার স্বয়ংক্রিয় মনিটরিং এবং নিয়ন্ত্রণ সক্ষম করে। বিভিন্ন আকার এবং আকৃতির ট্যাঙ্কের জন্য নন-কনট্যাক্ট ট্যাঙ্ক লেভেল সেন্সরগুলির নমনীয়তা এগুলিকে উপযুক্ত করে তোলে, যখন এদের রক্ষণাবেক্ষণমুক্ত কার্যপ্রণালী পরিচালন খরচ উল্লেখযোগ্যভাবে কমিয়ে দেয়। ফেন, বাষ্প এবং অস্থির অবস্থার মধ্য দিয়ে পরিমাপের ক্ষমতা জটিল শিল্প প্রক্রিয়াগুলিতে নির্ভরযোগ্য পাঠ নিশ্চিত করে।