Introduction

Photoelectric and mechanical switches — two types of sensors and control devices involved in a variety of automated processes that perform similar functions but with drastically different operating principles, are some examples. The differences are important for engineers and technicians to recognize in choosing the right switch for a given application. In this article, we will discuss the basic differences between photoelectric switch and mechanical switch in relation to their operations, components, environmental parameters, speed and accuracy, application and costs.

Operational Principles

Judging whether or not there is an object by emitting and sensing light – photoelectric switch is the basic principle of operation characteristic embedded with a photoelectric effect. Its a non-contact switch, This type of switch work without any physical contact. A mechanical switch, on the other hand, does this by physical contact or proximity to create or break an electrical circuit. It consists of various moving parts that interact with one another when the switch is flipped.

Components and Construction

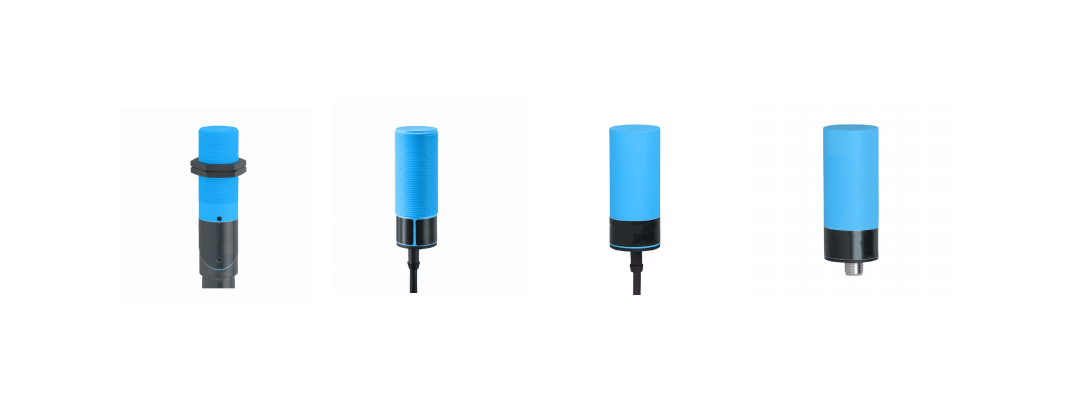

A photoelectric switch comprises a light source, typically an LED or laser, as well as a photo-detector such as a photo-diode or photo-transistor, and electronic circuitry for the purpose of signal processing. That's different from a mechanical switch, which has an actuator like a button, lever, or proximity sensor, contact points that are typically made of metal and housing to enclose all those components.

Types and Variations

Photoelectric switches features several types of photoelectric switches: retro-reflective switch that bounce off a reflective surface, through-beam sensors that detect interruptions in a light beam, and diffuse reflective sensors using light bounced from the object. On the other hand, mechanical switches are classified depending upon their physical structure which could be push-button switch, toggle switch and proximity switch; this type of switch works by a magnetic field.

Endurance and Environmental Conditions

The major contrast amidst the several is their flexibility to environmental elements. Because they have no moving parts, the performance of photoelectric switches is less susceptible to physical wear and tear. But they can be affected by any conditions that obstruct light including dust and fog. Since mechanical switches have moving parts, they are susceptible to wearing down over time, but otherwise resist environmental factors that might otherwise affect physical components.

Speed and Accuracy

Photoelectric switches are much faster, and their accuracy is higher, given that they can detect objects with precision for high-speed applications. Response times also vary based on the type of mechanical switch, and accuracy may be degraded by physical tolerances in manufacturing affecting contact size and movement or erosion of the contacts.

Applications and Industries

It depends on application when to go for either a photoelectric or a mechanical switch. These components are commonly found in various applications like automation, safety systems, and robotics that require non-contact sensing. Mechanical switches are easy to use and durable switches that include a simple electrical circuit like in all appliances and machinery that requires physical interaction.

Cost and Maintenance

The cost and maintenance of the different types of switches can greatly differ. Photoelectric switches might be slightly more expensive (upfront) – because they are a newer technology – but such devices normally require less maintenance as there are also no moving parts. Mechanical switches are physically cheaper but usually require more maintenance since contacts and such wear out.

Conclusion

Ultimately the decision of photoelectric vs mechanical switch depends on the application. Photo-controls are also non-working, speedier and extremely accurate switches utilized in computerization of high-tech locations. Due to their robustness and lower price point, mechanical switches are only appropriate for physical interaction solutions primarily where form factor and cost ratio is critical. Both of these switch types have evolved over the years alongside technology and now feature improved performances and additional functionality. These differences are essential to know in order to pick the right switch for any job to perform well and never fail.