Understanding the Power of Ultrasonic Technology in Modern Automation

The integration of ultrasonic sensor technology has revolutionized the landscape of industrial automation, offering unprecedented levels of precision and reliability in various applications. From manufacturing processes to robotics, these sophisticated devices have become instrumental in achieving superior automation accuracy. By utilizing high-frequency sound waves to detect objects and measure distances, ultrasonic sensors provide reliable data that enables automated systems to make more informed decisions and execute tasks with greater precision.

The fundamental principle behind ultrasonic sensor operation involves emitting sound waves and measuring the time taken for these waves to bounce back after hitting an object. This simple yet effective mechanism has proven invaluable across numerous industries, where accurate distance measurement and object detection are crucial for maintaining operational efficiency and product quality.

Core Components and Functionality of Ultrasonic Sensing Systems

Essential Hardware Elements

At the heart of an ultrasonic sensor lies a sophisticated arrangement of components working in harmony. The transducer, which acts as both emitter and receiver, generates high-frequency sound waves and captures their echoes. The timing circuit measures the travel time of these waves with remarkable precision, while the signal processing unit converts this information into usable data. Supporting electronics, including amplifiers and filters, ensure the clarity and reliability of the measurements.

Modern ultrasonic sensors also incorporate temperature compensation mechanisms, as sound wave velocity varies with ambient temperature. This additional feature helps maintain accuracy across different environmental conditions, making these sensors highly adaptable to various industrial settings.

Signal Processing and Data Interpretation

The effectiveness of an ultrasonic sensor largely depends on its ability to process and interpret received signals accurately. Advanced algorithms filter out noise and unwanted echoes, focusing on relevant data that indicates true object presence or distance. The sensor's microprocessor analyzes the filtered signals, applying calibration factors and environmental compensations to produce highly accurate measurements.

Real-time signal processing capabilities enable these sensors to adapt to changing conditions and maintain consistent performance. This dynamic adjustment capability makes ultrasonic sensors particularly valuable in automated systems where environmental factors frequently fluctuate.

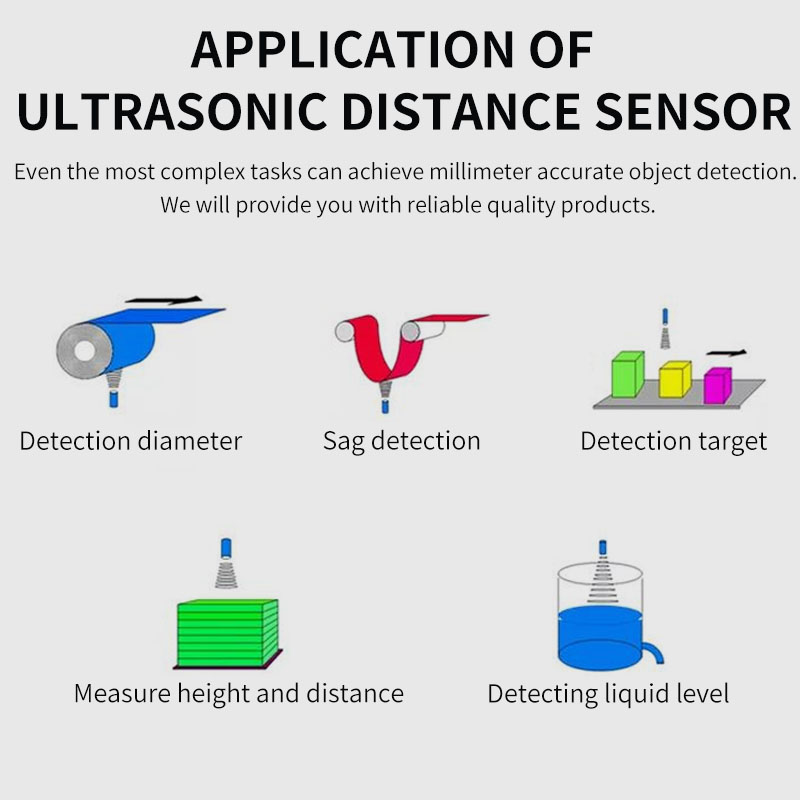

Applications Across Industrial Automation

Manufacturing Process Control

In manufacturing environments, ultrasonic sensors play a crucial role in ensuring precise material handling and quality control. These devices excel at monitoring fill levels in containers, detecting product presence on conveyor belts, and maintaining proper spacing between items during production. Their non-contact measurement capability makes them ideal for handling delicate materials or working in environments where physical contact might compromise product integrity.

The implementation of ultrasonic sensors in automated assembly lines has significantly reduced error rates and improved production efficiency. By providing real-time feedback about product positioning and movement, these sensors enable automated systems to make instant adjustments, maintaining optimal production flow.

Robotics and Automated Guidance Systems

The integration of ultrasonic sensors in robotics has revolutionized automated navigation and obstacle avoidance. These sensors provide robots with crucial spatial awareness, enabling them to move safely and efficiently through dynamic environments. In warehouse automation, ultrasonic sensors guide automated guided vehicles (AGVs) with remarkable precision, ensuring smooth operation in confined spaces.

Advanced robotics applications utilize multiple ultrasonic sensors to create comprehensive environmental mapping, enabling more sophisticated movement and interaction capabilities. This multi-sensor approach provides redundancy and enhanced accuracy, crucial for applications requiring precise positioning and object manipulation.

Enhancing Accuracy Through Technical Optimization

Calibration and Maintenance Protocols

Maintaining optimal performance of ultrasonic sensors requires regular calibration and proper maintenance procedures. Environmental factors such as temperature, humidity, and air pressure can affect sensor accuracy, making periodic calibration essential. Implementing structured maintenance schedules helps ensure consistent performance and extends sensor lifespan.

Advanced calibration techniques often involve comparing sensor readings against known reference standards under various operating conditions. This comprehensive approach helps identify and compensate for any systematic errors, ensuring reliable measurements across the sensor's entire operating range.

Environmental Considerations and Adjustments

Successfully implementing ultrasonic sensors requires careful consideration of environmental factors that might affect their performance. Acoustic interference, temperature variations, and air turbulence can all impact measurement accuracy. Understanding these factors enables proper sensor placement and the implementation of appropriate protective measures.

Modern ultrasonic sensors often include built-in environmental compensation features, but optimal performance still requires thoughtful installation planning. This might include installing acoustic barriers, maintaining stable temperature conditions, or implementing multiple sensor arrays for enhanced reliability in challenging environments.

Future Developments and Emerging Technologies

Integration with AI and Machine Learning

The future of ultrasonic sensor technology lies in its integration with artificial intelligence and machine learning systems. These advanced algorithms can analyze sensor data patterns to predict maintenance needs, optimize performance, and adapt to changing conditions automatically. This integration enables more sophisticated automation capabilities and improved system reliability.

Machine learning algorithms can help ultrasonic sensors better distinguish between relevant signals and noise, improving their accuracy in complex environments. This enhanced signal processing capability opens up new applications in increasingly challenging industrial settings.

Advanced Materials and Design Innovations

Ongoing research in transducer materials and sensor design continues to push the boundaries of what's possible with ultrasonic technology. New piezoelectric materials and innovative sensor configurations are enabling higher precision, greater range, and improved reliability. These advances are making ultrasonic sensors even more valuable in automation applications.

The development of more compact and energy-efficient designs is also making it possible to deploy ultrasonic sensors in previously impractical applications. This expansion of capabilities is driving new innovations in automated systems across various industries.

Frequently Asked Questions

What factors can affect ultrasonic sensor accuracy?

Ultrasonic sensor accuracy can be influenced by several factors including ambient temperature, humidity, air pressure, acoustic interference, and the surface characteristics of target objects. Environmental noise, vibrations, and the presence of dust or vapor in the air can also impact measurement reliability.

How often should ultrasonic sensors be calibrated?

The calibration frequency depends on the application and operating environment, but generally, industrial ultrasonic sensors should be calibrated every 6-12 months. More frequent calibration may be necessary in harsh environments or for applications requiring extremely high precision.

What is the typical measurement range of industrial ultrasonic sensors?

Industrial ultrasonic sensors typically offer measurement ranges from a few centimeters up to several meters. High-end sensors can measure distances up to 15 meters or more, though the exact range depends on the sensor model, environmental conditions, and the target object's characteristics.