Understanding the Impact of Modern Sensing Technology in Industry

The industrial landscape is undergoing a remarkable transformation, with proximity sensor technology emerging as a cornerstone of automation and efficiency. These sophisticated devices are revolutionizing how manufacturing facilities, warehouses, and processing plants operate, offering unprecedented levels of precision and control in detecting objects and materials without physical contact. As industries worldwide seek to optimize their operations and boost productivity, proximity sensor integration has become increasingly vital to achieving these objectives.

Modern industrial facilities leverage proximity sensor technology to automate countless processes, from assembly line operations to quality control inspections. These sensors act as the eyes and ears of industrial machinery, enabling split-second decisions that maintain production flow while ensuring worker safety. The technology's ability to detect objects reliably, regardless of lighting conditions or environmental factors, makes it an indispensable tool in today's competitive manufacturing environment.

Core Benefits of Proximity Sensor Implementation

Enhanced Operational Efficiency

When integrated properly, proximity sensor systems dramatically improve operational efficiency across various industrial applications. These devices enable continuous monitoring of production lines, ensuring precise positioning of components and maintaining optimal spacing between materials. The result is a significant reduction in production errors and increased throughput, as machines can operate at peak efficiency without the delays associated with manual monitoring.

The implementation of proximity sensor technology also leads to reduced downtime. By detecting potential issues before they cause system failures, these sensors enable predictive maintenance strategies that keep production lines running smoothly. This proactive approach to equipment maintenance has proven to increase overall equipment effectiveness (OEE) by as much as 25% in many industrial settings.

Improved Safety Standards

Safety remains a paramount concern in industrial environments, and proximity sensor technology plays a crucial role in protecting both workers and equipment. These sensors create invisible safety barriers around dangerous machinery, automatically halting operations when unauthorized access is detected. This capability has significantly reduced workplace accidents and associated costs in facilities where the technology has been properly implemented.

Beyond immediate safety benefits, proximity sensor systems also contribute to long-term risk reduction by monitoring equipment wear and potential failure points. This preventive approach helps maintain a safer working environment while ensuring compliance with increasingly stringent safety regulations.

Technical Considerations for Implementation

Sensor Selection and Placement

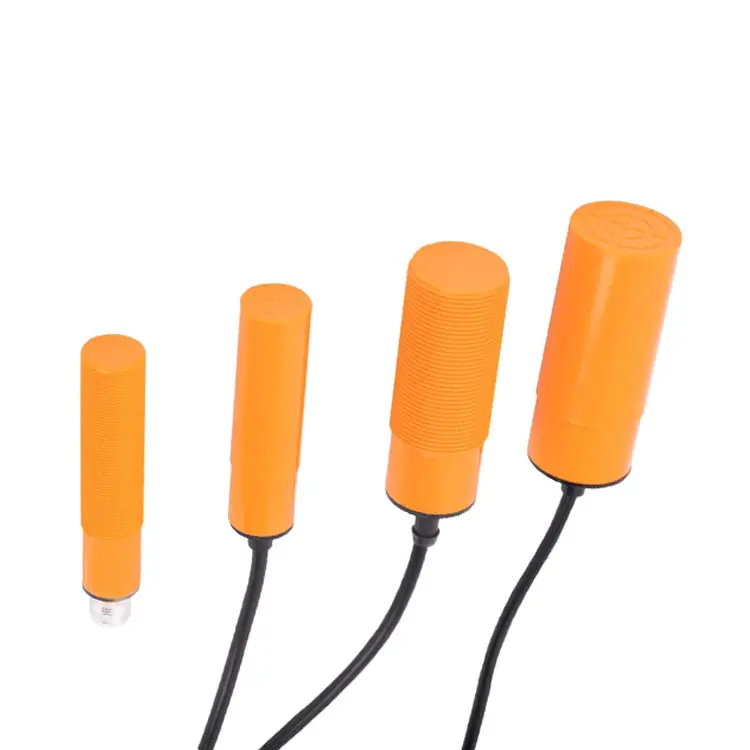

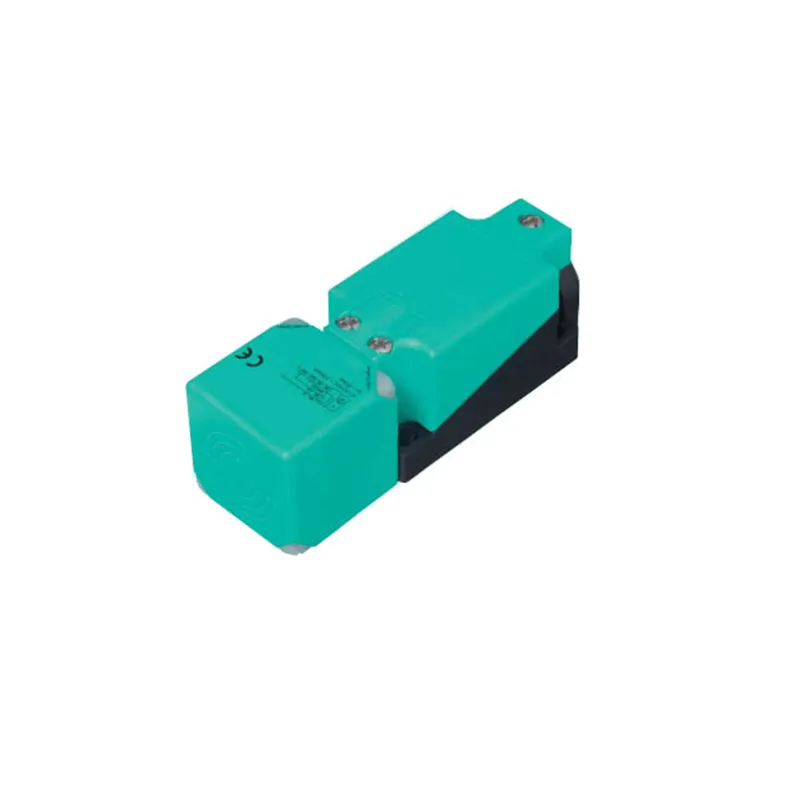

Choosing the right proximity sensor for specific industrial applications requires careful consideration of several factors. Environmental conditions, target material properties, and required detection range all play crucial roles in sensor selection. Inductive proximity sensors excel in metal detection applications, while capacitive variants offer superior performance with non-metallic materials.

Optimal sensor placement is equally important for maximizing system effectiveness. Strategic positioning ensures reliable detection while minimizing false triggers that could disrupt production flow. Engineers must consider factors such as mounting stability, interference from nearby equipment, and accessibility for maintenance when determining sensor locations.

Integration with Existing Systems

Successfully incorporating proximity sensor technology into existing industrial infrastructure demands a well-planned integration strategy. This includes ensuring compatibility with current control systems, establishing proper communication protocols, and implementing appropriate signal processing mechanisms. Modern proximity sensor systems often feature advanced connectivity options, allowing seamless integration with industrial IoT networks and data analytics platforms.

The integration process should also account for future scalability, enabling the addition of more sensors or expanded functionality as operational needs evolve. This forward-thinking approach helps protect the initial investment while providing flexibility for future growth.

Economic Impact and ROI Analysis

Cost Reduction Opportunities

The implementation of proximity sensor technology often results in substantial cost savings across multiple operational areas. Reduced material waste, decreased maintenance expenses, and lower energy consumption are common benefits that directly impact the bottom line. Manufacturing facilities have reported operational cost reductions of up to 30% following comprehensive proximity sensor deployment.

Labor costs also tend to decrease as proximity sensor systems automate previously manual inspection and monitoring tasks. This automation allows workforce reallocation to higher-value activities, improving overall operational efficiency while maintaining employment levels.

Long-term Financial Benefits

While the initial investment in proximity sensor technology may seem significant, the long-term financial benefits typically justify the expense. Improved product quality leads to higher customer satisfaction and reduced warranty claims, while enhanced equipment reliability results in extended machinery lifespan. These factors contribute to a strong return on investment, often realized within 12-18 months of implementation.

The technology's contribution to predictive maintenance strategies also generates substantial savings by preventing costly emergency repairs and unplanned downtime. This proactive approach to equipment maintenance can reduce maintenance costs by up to 40% while extending machine service life.

Future Trends and Technology Evolution

Advanced Sensing Capabilities

The future of proximity sensor technology promises even greater capabilities and applications. Emerging developments include enhanced sensitivity, longer detection ranges, and improved resistance to environmental interference. Integration with artificial intelligence and machine learning algorithms will enable more sophisticated object recognition and predictive capabilities.

Research is also underway to develop new types of proximity sensors that can detect additional physical properties beyond presence and distance. These innovations will expand the technology's applications and further increase its value in industrial settings.

Industry 4.0 Integration

As Industry 4.0 continues to reshape manufacturing, proximity sensor technology will play an increasingly central role in connected industrial systems. The integration of smart sensors with industrial IoT platforms enables real-time data collection and analysis, supporting advanced automation and optimization strategies. This connectivity also facilitates remote monitoring and management capabilities, essential for modern industrial operations.

The evolution of proximity sensor technology will continue to drive improvements in industrial productivity, making it an essential component of future manufacturing systems. Companies that embrace these technological advances position themselves for sustained competitive advantage in an increasingly automated industrial landscape.

Frequently Asked Questions

What is the typical lifespan of industrial proximity sensors?

Industrial proximity sensors typically last between 5 to 10 years when properly maintained, though this can vary based on environmental conditions and usage patterns. Regular maintenance and appropriate protection from harsh conditions can significantly extend sensor life.

How do proximity sensors perform in extreme industrial environments?

Modern industrial proximity sensors are designed to withstand challenging conditions, including high temperatures, humidity, and vibration. Special variants are available for extreme environments, featuring enhanced protection ratings and robust construction for reliable operation.

What maintenance requirements do proximity sensors have?

Proximity sensors generally require minimal maintenance, mainly consisting of regular cleaning, inspection for physical damage, and periodic calibration checks. Most manufacturers recommend quarterly inspections and annual comprehensive evaluations to ensure optimal performance.