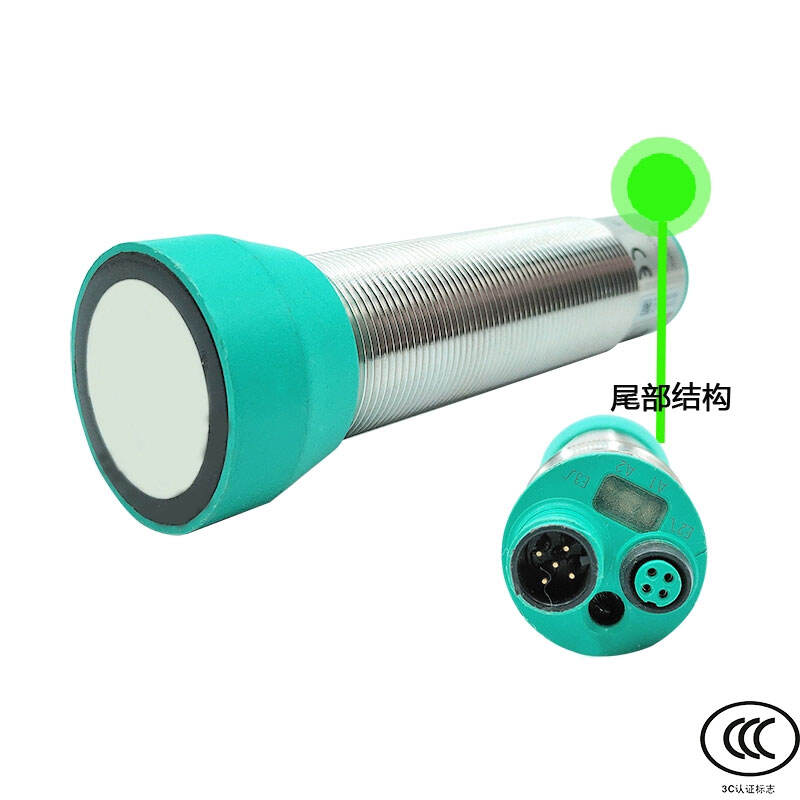

ultrasonic fuel sensor

The ultrasonic fuel sensor represents a cutting-edge solution for accurate fuel level measurement in various vehicles and storage tanks. This sophisticated device employs ultrasonic wave technology to precisely determine fuel levels by measuring the time taken for sound waves to travel from the sensor to the fuel surface and back. Operating on the principle of echo location, the sensor emits high-frequency sound waves that bounce off the fuel surface, providing real-time, continuous monitoring of fuel levels with exceptional accuracy. The sensor's advanced digital processing capabilities enable it to compensate for various factors such as temperature changes and fuel density variations, ensuring consistent and reliable measurements. The device is engineered with robust materials that resist corrosion and withstand harsh environmental conditions, making it suitable for both commercial and industrial applications. Its non-intrusive measurement technique eliminates the need for direct contact with the fuel, reducing wear and tear while extending the sensor's operational lifespan. The ultrasonic fuel sensor interfaces seamlessly with modern vehicle management systems and can be integrated with fleet management software to provide comprehensive fuel consumption analytics and theft prevention capabilities.