range of ultrasonic

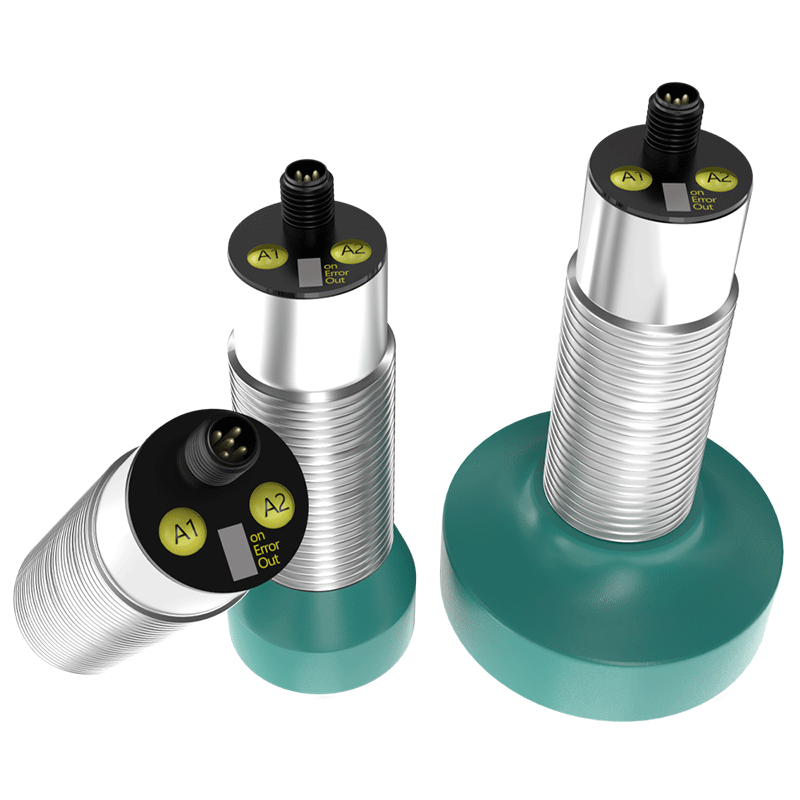

The range of ultrasonic technology represents a groundbreaking advancement in industrial and medical applications, utilizing high-frequency sound waves beyond human hearing capabilities. Operating at frequencies typically between 20 kHz and several gigahertz, these systems offer unprecedented precision in various applications. The technology employs piezoelectric transducers to convert electrical signals into mechanical vibrations, generating ultrasonic waves that can penetrate materials, measure distances, and perform cleaning operations. Modern ultrasonic systems feature advanced digital control interfaces, real-time monitoring capabilities, and adjustable frequency settings to accommodate different materials and applications. These systems excel in non-destructive testing, medical imaging, industrial cleaning, and quality control processes. The technology includes sophisticated filtering algorithms to eliminate noise and enhance signal clarity, ensuring accurate results across diverse operating conditions. Contemporary ultrasonic ranges incorporate smart calibration systems, automated parameter adjustment, and data logging capabilities, making them essential tools in manufacturing, healthcare, and research settings.