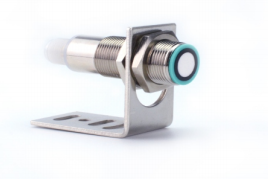

photoelectric sensor in logistics automation

Photoelectric sensors play a pivotal role in modern logistics automation, serving as essential components for precise detection and monitoring in warehouse operations. These sophisticated devices utilize light-based technology to detect the presence, absence, or distance of objects along conveyor systems and automated sorting lines. The sensor consists of an emitter that projects a beam of light and a receiver that detects changes in the light pattern, enabling accurate object detection and measurement. In logistics automation, these sensors excel in various applications, including package detection, height verification, object counting, and position monitoring. The technology supports both through-beam and retro-reflective configurations, allowing for flexible installation options based on specific operational requirements. Advanced models incorporate features such as background suppression, which enables reliable detection regardless of object color or reflectivity, and digital filtering to minimize false triggers in dusty environments. The sensors can operate at high speeds, making them ideal for fast-moving conveyor systems and sorting applications. Additionally, modern photoelectric sensors often include smart diagnostics and IO-Link compatibility, enabling seamless integration with warehouse management systems and providing valuable operational data for predictive maintenance.