industrial ultrasonic sensor cost

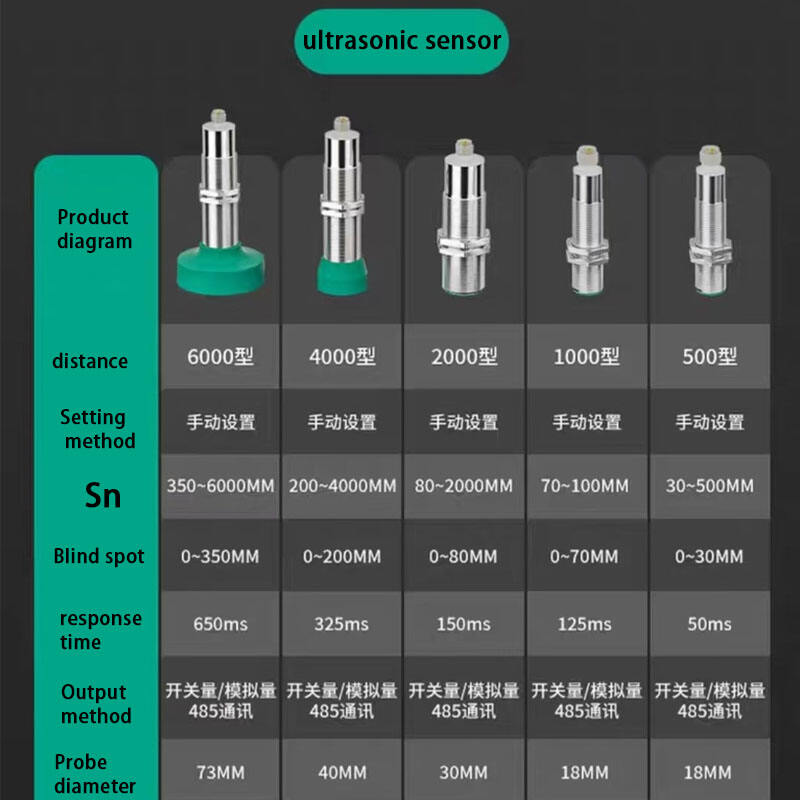

Industrial ultrasonic sensor cost encompasses various factors that influence the overall investment in these essential measurement devices. These sensors, typically ranging from $100 to $1000 depending on specifications, utilize high-frequency sound waves to detect objects and measure distances with remarkable precision. The cost varies based on features such as measurement range, accuracy levels, environmental protection ratings, and communication protocols. Entry-level sensors suitable for basic distance measurement in clean environments generally fall in the lower price range, while advanced models with extended capabilities such as temperature compensation, multiple output options, and hazardous area certifications command premium prices. The investment also includes consideration of installation requirements, maintenance needs, and potential integration costs with existing control systems. Modern industrial ultrasonic sensors often incorporate smart features like self-diagnostic capabilities, digital displays, and programmable parameters, which can affect the initial purchase price but potentially reduce long-term operational costs. These sensors find widespread applications in level measurement, object detection, and position monitoring across industries including manufacturing, chemical processing, and material handling.